Diameter: High Strength Friction Grip Nut & Bolts

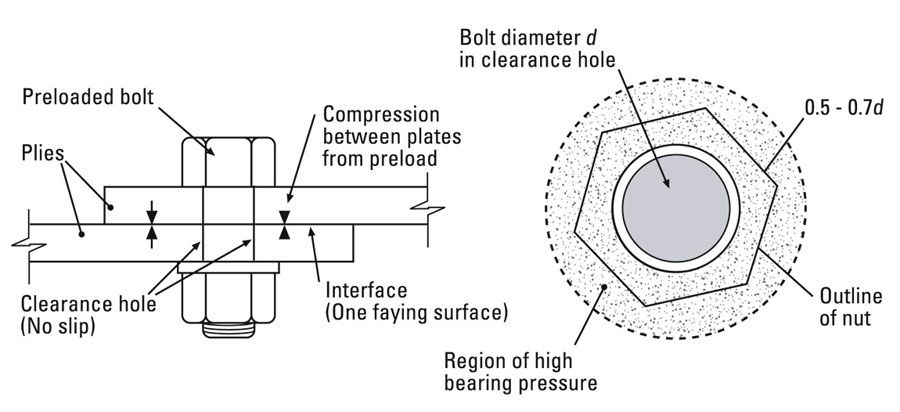

IS 4000 gives diameters of HSFG bolts as M16, M20, M24, M30 and M36. Other sizes given in IS 1367 include M18, M22 and M27 (Referred to as ‘non-preferred’ sizes also). … Maximum grip length of all plies, including packings and packing washers, shall not exceed 10 times the nominal diameter of the bolt.

HSFC nuts are durable from other nuts and can tolerate the extreme stress. Some types of nuts are; Nylon insert lock, jam, Hex, Heavy Hex, Nylon insert lock, jam, Nylon insert jam lock, wing, Tee, Cap, Acorn, Square, Flange, Prevailing torque lock, K lock or Kep, torque lock, Coupling, Slotted Castle. The dimension of the High strength friction grip nut or HSFG Nut is accurate, the finish of these nuts is flawless, and it has robust designs. For the advance industry, HSFG Nuts are in heavy demand.